RF/EMI Shielded Walk-In Tent (Faraday Tent)

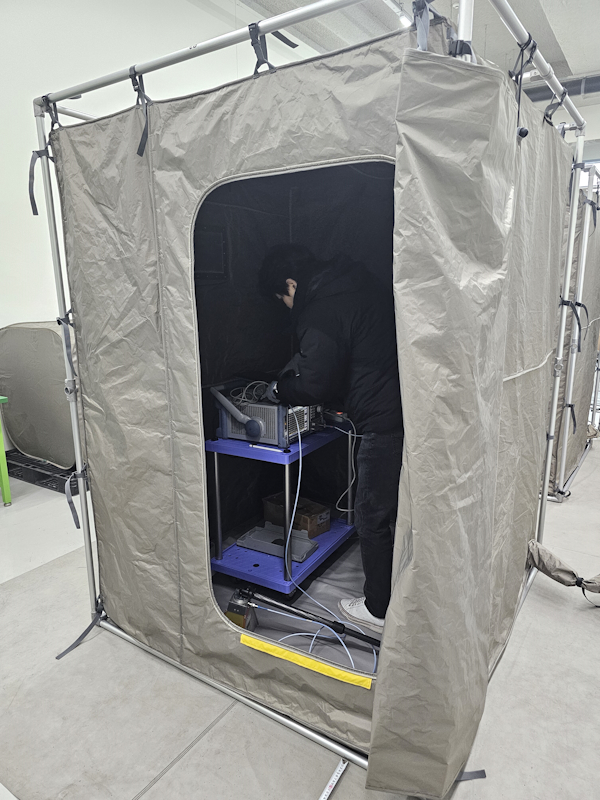

- RF/EMI Shielded Walk-In Tent comfortably accommodates operator(s) with ample space for multiple pieces of equipment.

- Constructed of plated fabric with excellent electrical conductivity and high shielding effectiveness, this soft-wall tent can be used as an alternative to a metal-wall shielded chamber.

- It has a prefabricated structure and is easy to install/move/dismantle, so it can be used in a variety of places and purposes.

Features

- Excellent flexibility and electrical conductivity due to use of metal-coated fabric (SE: average -80dB, up to -90dB)

- Magnetic seal door system provides easy opening and closing. (within 3 seconds)

- Economical replacement for metal shielded chamber

- In addition to standard sizes, custom sizes can be made according to customer requirements.

- Specifications

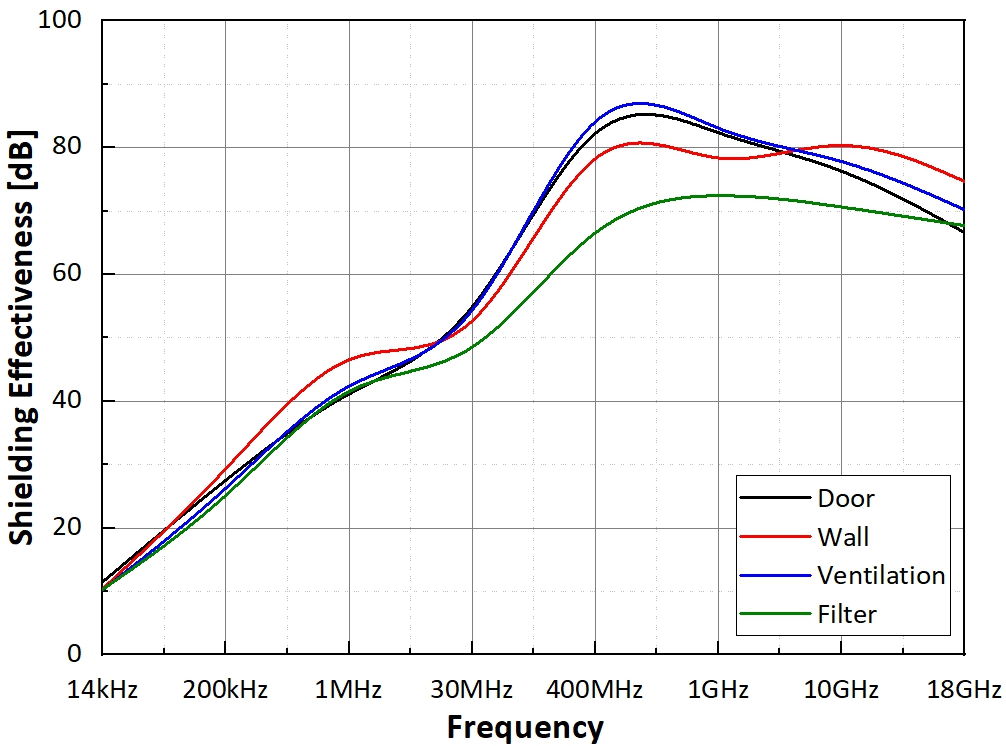

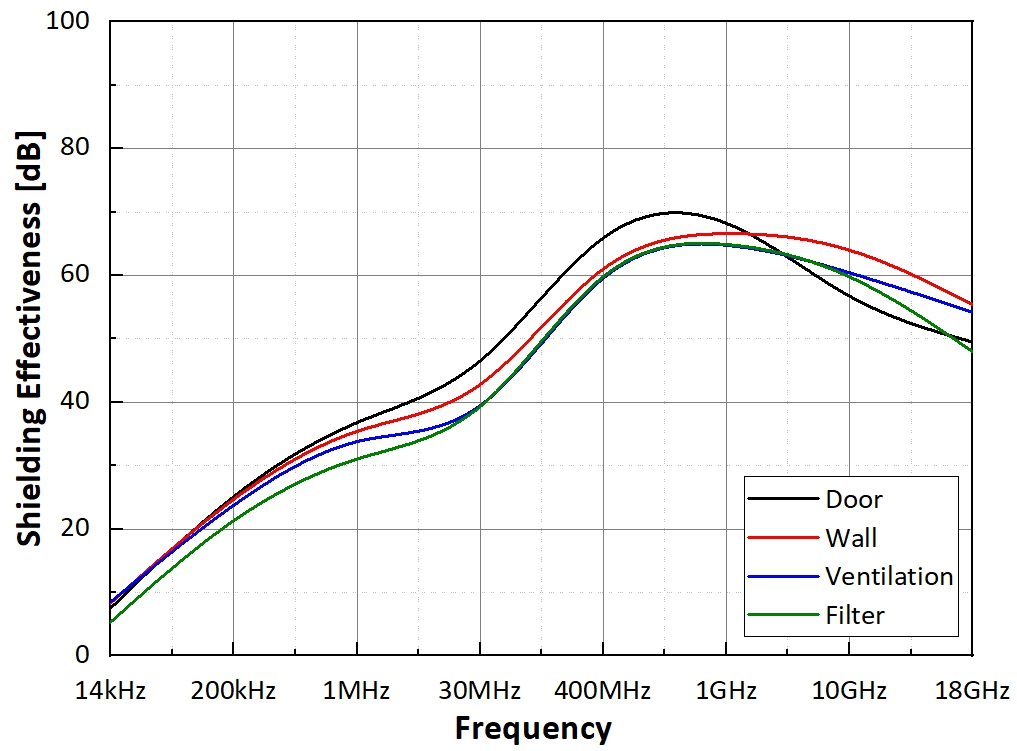

- Shielding Effectiveness

- Options

- Applications

-

HST Series (Hi-Shielded Tent)

- Shielding Effectiveness: Average 80dB at 400MHz

- Tent Wall (Fabric): Significantly improved shielding effectiveness by laminating specially processed layer to Ni/Cu/Ni plated polyester fabric

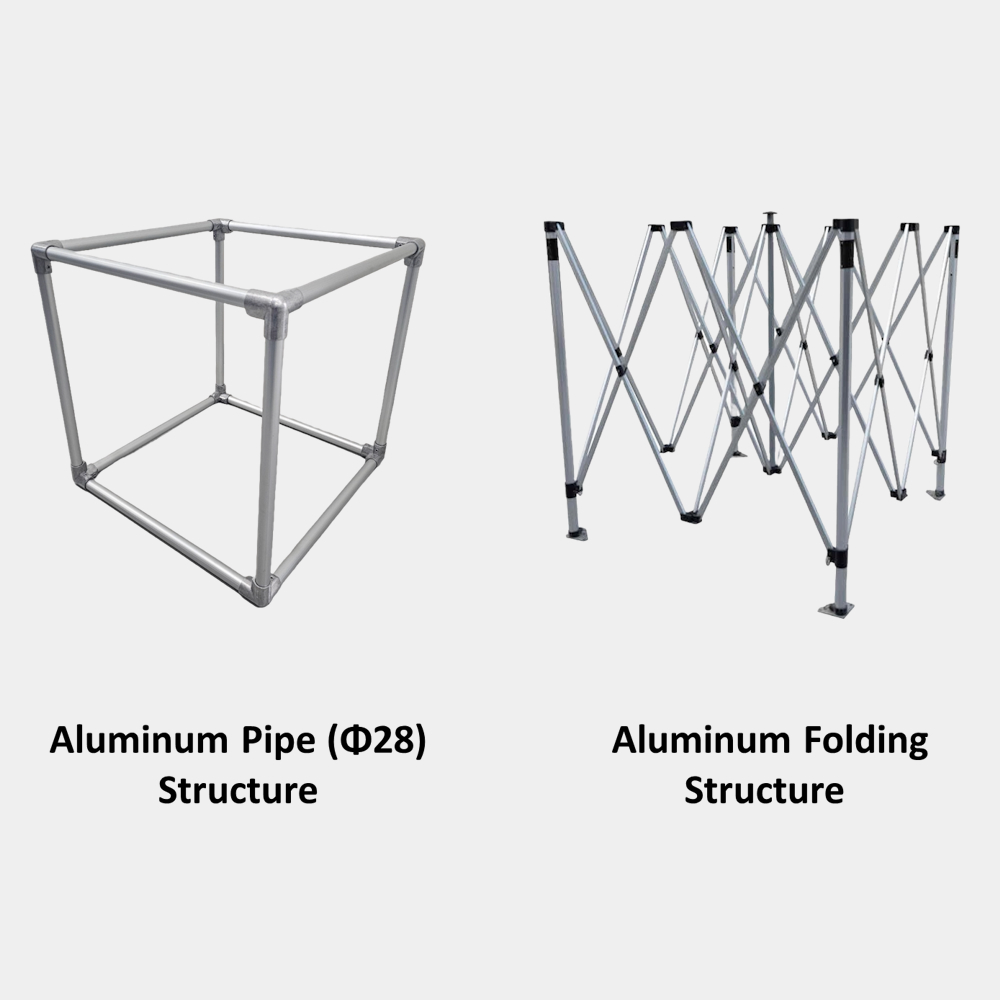

- Frame: Aluminum tube (Φ28) or Aluminum folding frame available.

- Door Sealing: Available in magnetic plate or double zipper fastener style.

* Magnetic door sealing method is easy to open and close, enabling opening and closing within 3 seconds.

ST Series (Shielded Tent)

- Shielding Effectiveness: Average 60dB at 400MHz

- Tent Wall (Fabric): Ni/Cu/Ni plated polyester fabric

- Frame: Aluminum tube (Φ28) or Aluminum folding frame available.

- Door Sealing: Available in magnetic plate or double zipper fastener style.

Standard Sizes

- W 2.0 * H 2.0 * L 2.0 m

- W 3.0 * H 2.0 * L 3.0 m

-

HST Series (Hi-Shielded Tent)

- IEEE® 299:2006 Standard Testing

- Excellent shielding performance in 400MHz to 10GHz band, which is a main communication frequency band such as cellular, Wi-Fi and 5G.

ST Series (Shielded Tent)

- IEEE® 299:2006 Standard Testing

- Excellent shielding performance of over 60dB on average in the 400MHz to 10GHz band, which is a major communication frequency band such as mobile, Wi-Fi, and 5G.

Shielding Effectiveness Measurement

* IEEE® 299:2006 Standard Testing

-

Tent Options

- Glove box type

You can operate the device through the shielded window by putting your hand inside the tent wearing a shielded glove. - Wall fabric insulation type

Suitable for areas where there is a risk of electrical contact around where the shielded tent is to be installed. - Floor separation type

The bottom/floor of the shielded tent can be separated. Heavy objects are installed in advance and then covered with the tent to shield the heavy objects. - Threshold separation type

The lower threshold at the entrance to the shielded tent can be separated, allowing carts to enter and exit. - Double wall type

By installing a double wall tent, the shielding effect can be greatly improved. - Metal door type

It is suitable for applications with frequent entry and exit by installing a shielded room metal door only and attaching a shielded fabric tent to the rest.

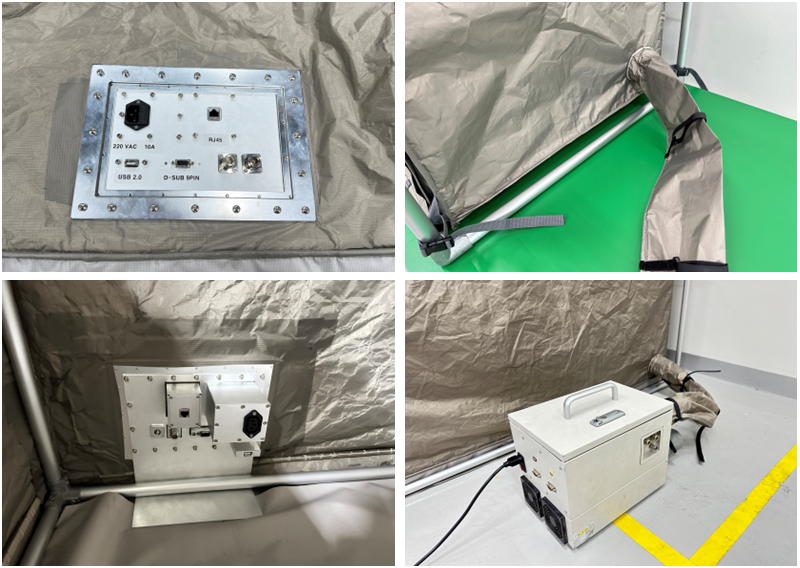

Part Options

- Interior fabric color available in white or light blue.

* Reduces operator eye fatigue when working for a long time inside a tent. - EMI filter I/O panel (Tent-attached type)

- EMI filter I/O box (Stand-alone type)

- Honeycomb vent

- Mesh window

- Internal lighting

- Internal smoke detector

- External warning lights

- Zipper tube (cable jacket) for cable shielding

- Conductive hot-melt adhesive tape

- Other materials available

- Glove box type

-

Applications