HQ / Seoul

+82-2-2082-5420

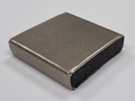

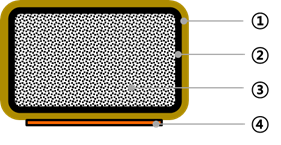

| Number | Material |

|---|---|

| 1 | Electrically conductive fabric |

| 2 | Graphite sheet |

| 3 | Heat-resistant foam |

| 4 | Adhesive tape |

| Properties | Unit | Typical Value | Test Method |

|---|---|---|---|

| Thermal conductivity | W/mK | > 2 | ASTM C 518 ASTM E 1530-06 |

| Z-axis resistance | Ω | < 0.1 | ESQ-612-02 |

| Operating temperature | °C | < 125 | ESQ-612-20 |

| Recommended compression rate | % | 25 | ESQ-612-27 |

| Compression recovery rate | % | > 90 | ESQ-612-26 |

| Environmental issue | - | RoHS-compliant, Halogen free | |

Thermal conductive performance is equal to that of the existing TFG, and the resistance is less than 0.1 Ω.

| The existing TFG | Ground TFG | |

|---|---|---|

| Pictures |  |

|

| Specimen | Graphite 1 layer, 50mm x 50mm x 13T | |

| Average Reaching Time* | 82~84 sec. | 80~82 sec. |

| Saturation temperature[℃] | 62.0℃ | 61.7℃ |

| Z-axis resistance[Ω] | - | 0.03~0.04 (25% compression) |

* Average Reaching Time:

Thermal transferring performance comparison of TFG and Thermal Ground Gasket

(Specimens of the same size, W50*L50*T13mm)

1) Measure the temperature change after pressing the specimen 20% between the heating plates.

2) After heating the lower heating plate to 150℃ and laying the specimen on the lower heating plate, measure the time until the thermal sensor of the upper heating plate rises from the initial setting value of 40℃ to 60℃.

By attaching it between the heat source and the heat sink/metal case, you can see the effect of heat dissipation (heat conduction) and suppression of electromagnetic noise at the same time.

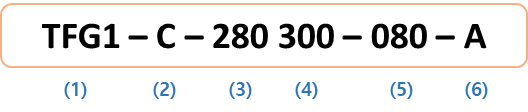

| # | Code | Examples |

|---|---|---|

| (1) | Product code | TFG1: Graphite 1 layer TFG2: Graphite 2 layers |

| (2) | Outer layer | C: Conductive fabric |

| (3) | Width (W) | 280: 28.0mm |

| (4) | Length (L) | 300: 30.0mm |

| (5) | Thickness (T) | 080: 8.0mm |

| (6) | Adhesive tape | A: T338, B: T324 |

No data.