HQ / Seoul

+82-2-2082-5420

Manufactured by inserting a inner cord material into the basic spiral gasket, the ribbon strip has the same specifications as the basic spiral gasket.

| Strip Material | Sn-plated BeCu | Ni-plated BeCu | Stainless Steel | |

|---|---|---|---|---|

| Strip | Material | Beryllium Copper C17200 | 304H | |

| Temper | XHM | - | ||

| Electrical Conductivity | 17~28 %IACS | - | ||

| - | Silicone Foam (F) | Silicone Rubber (A, T) | Test Method | |

|---|---|---|---|---|

| Inner Cord | Color | White | Translucent | - |

| Specific Gravity | 1.16 g/cm³ | 1.16 g/cm³ | JIS K 6220 | |

| Hardness (JIS A) | 53 | 61 | JIS K 6253 | |

| Tensile Strength | 91 Kgf/㎠ | 104 Kgf/㎠ | JIS K 6251 | |

| Elongation | 320 % | 365 % | JIS K 6251 | |

W: No Inner Cord

A: Silicone Solid

T: Silicone Tube

F: Silicone Foam

| P/N | Specifications | |||

|---|---|---|---|---|

| Strip Material | String Outer Diameter (OD) | Inner Cord (Core) | Force | |

| SBT-035W | Sn-plated BeCu | 3.5 mm | No inner cord (Coreless) | Standard |

| SBN-045A | Ni-plated BeCu | 4.5 mm | Silicone solid | Standard |

| PBT-040T | Sn-plated BeCu | 4.0 mm | Silicone Tube | Medium |

| FSN-050F | Stainless Steel | 5.0 mm | Silicone Foam | Low |

| P/N | Inner Cord | Compression Force (kgf/in.) | |||

|---|---|---|---|---|---|

| 10% Comp. | 20% Comp. | 30% Comp. | 40% Comp. | ||

| SSN-032W | No Inner Cord | 2.45 | 5.07 | 7.38 | 8.65 |

| SSN-032F | Silicone Foam | 2.79 | 5.78 | 8.49 | 10.73 |

| SSN-032T | Silicone Tube | 3.88 | 8.01 | 11.01 | 14.37 |

| SSN-032A | Silicone Solid | 3.90 | 8.91 | 13.93 | 20.81 |

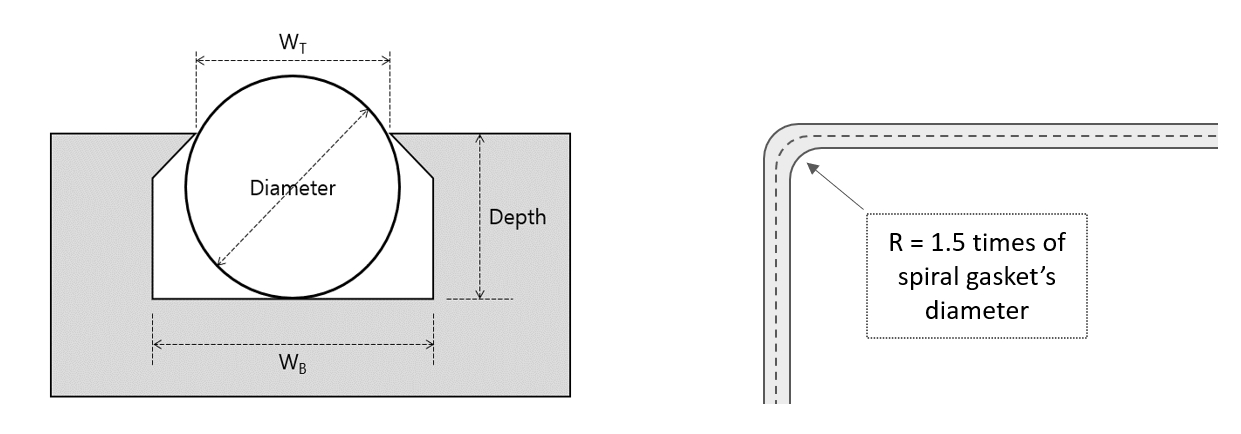

| String OD [mm] | Groove Size [mm] | ||

|---|---|---|---|

| Depth | WB | WT | |

| 1.0 | 0.75 | 1.35 | 0.96 |

| 2.0 | 1.50 | 2.70 | 1.92 |

| 2.2 | 1.65 | 2.97 | 2.11 |

| 2.4 | 1.80 | 3.24 | 2.30 |

| 2.6 | 1.95 | 3.51 | 2.50 |

| 2.8 | 2.10 | 3.78 | 2.69 |

| 3.0 | 2.25 | 4.05 | 2.88 |

| 3.2 | 2.40 | 4.32 | 3.07 |

| 3.4 | 2.55 | 4.59 | 3.26 |

| 3.6 | 2.70 | 4.86 | 3.46 |

| 3.8 | 2.85 | 5.13 | 3.65 |

| String OD [mm] | Groove Size [mm] | ||

|---|---|---|---|

| Depth | WB | WT | |

| 4.0 | 3.00 | 5.40 | 3.84 |

| 4.2 | 3.15 | 5.67 | 4.03 |

| 4.4 | 3.30 | 5.94 | 4.22 |

| 4.6 | 3.45 | 6.21 | 4.42 |

| 4.8 | 3.60 | 6.48 | 4.61 |

| 5.0 | 3.75 | 6.75 | 4.80 |

| 6.0 | 4.50 | 8.10 | 5.76 |

| 7.0 | 5.25 | 9.45 | 6.72 |

| 8.0 | 6.00 | 10.80 | 7.68 |

| 9.0 | 6.75 | 12.15 | 8.64 |

| 10.0 | 7.50 | 13.50 | 9.60 |

* Options avaiable by ribbon strip material, force, inner cord material, O-Ring, etc

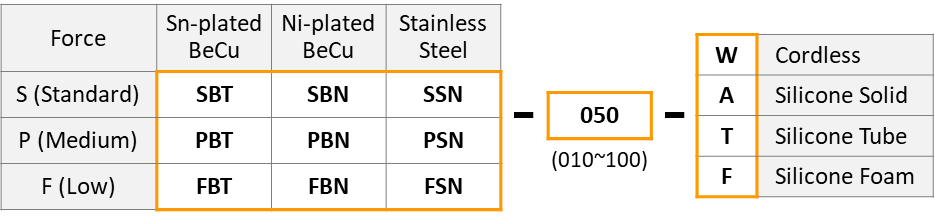

| Options | Codes |

|---|---|

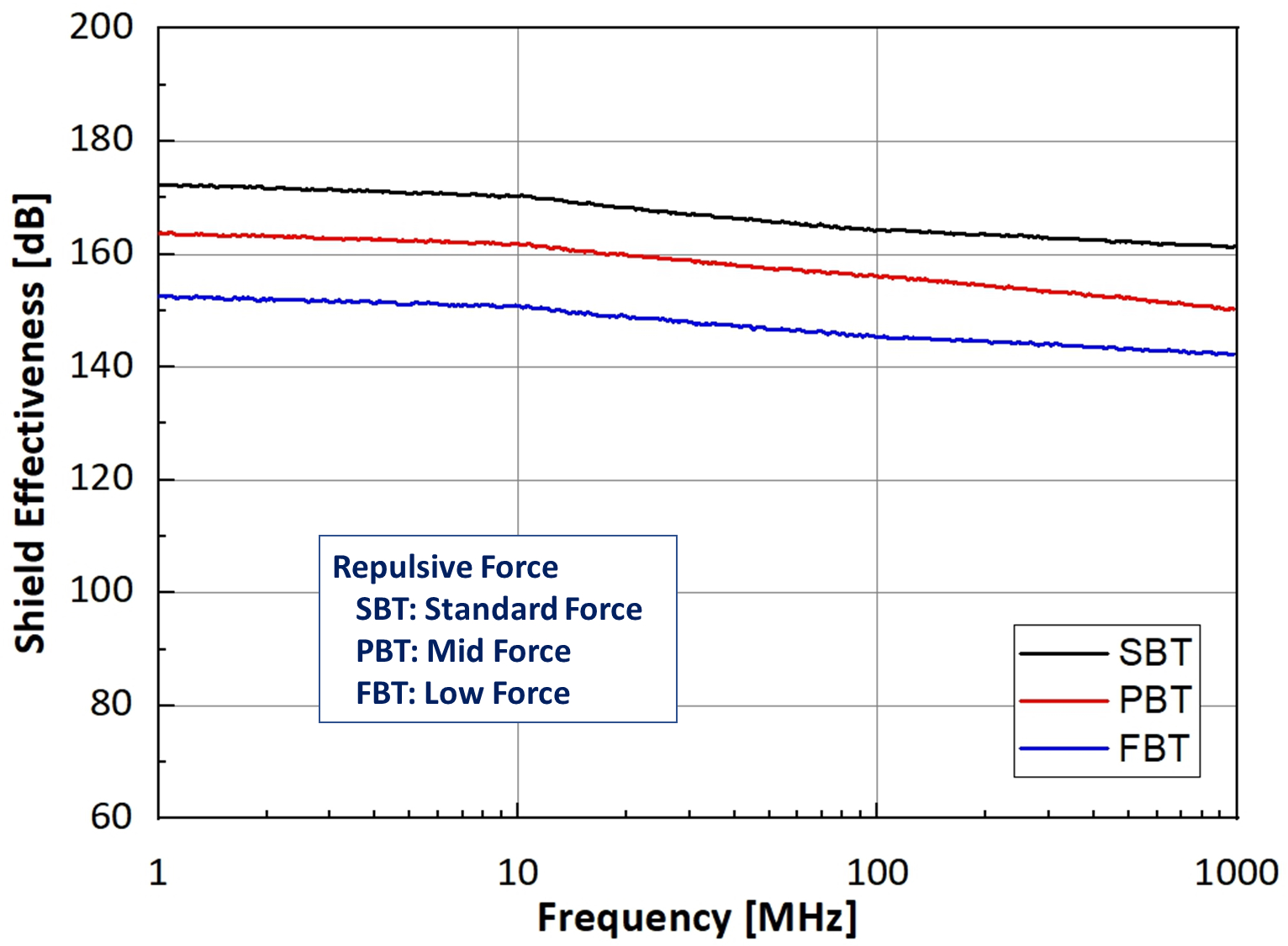

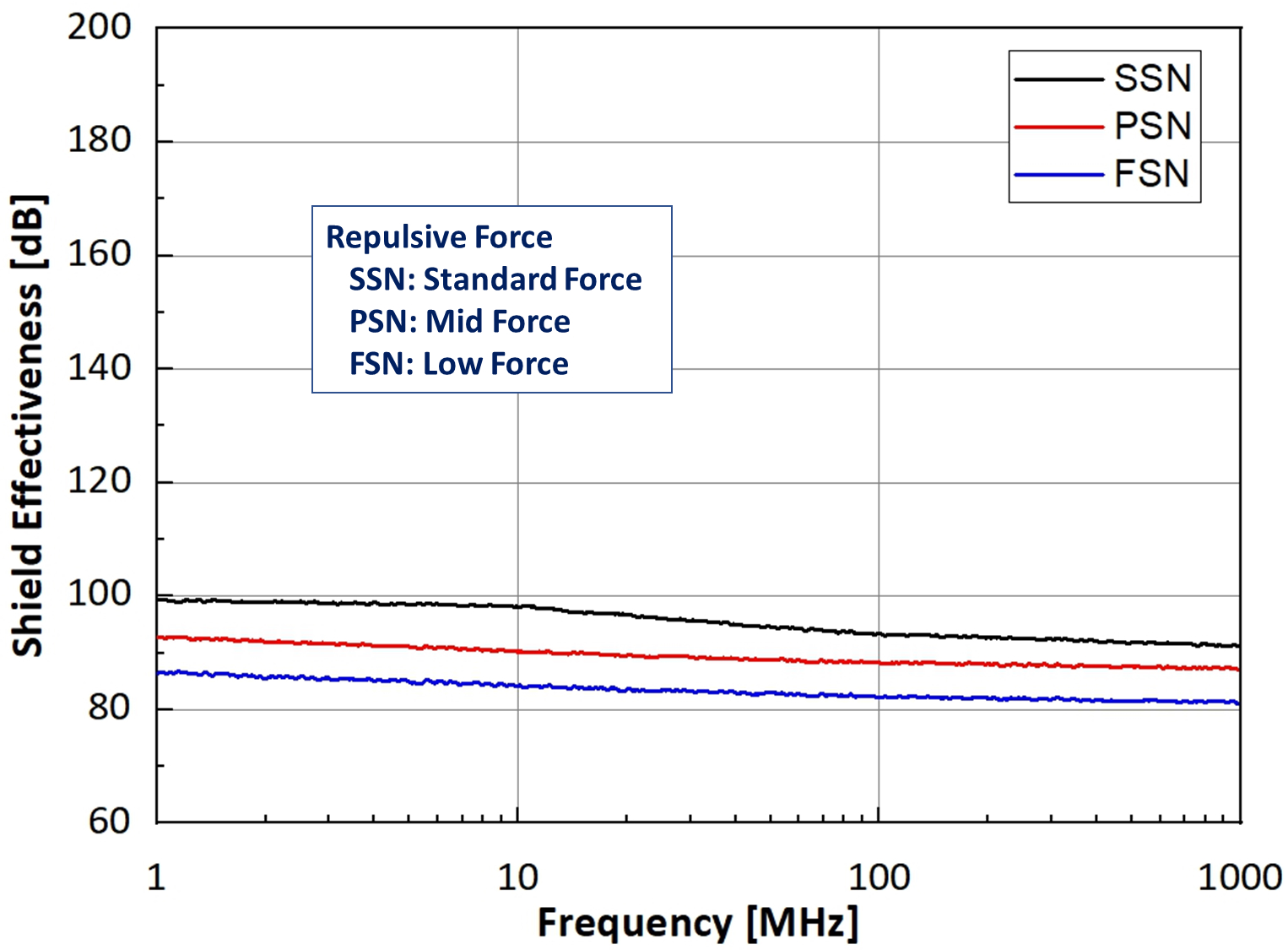

| Force | S: Standard Force, P: Medium Force, F: Low Force |

| Strip Material | BT: Sn plated BeCu, BN: Ni plated BeCu, SN: Stainless Steel |

| String OD (Ø) | 010~100 (1.0~10.0mm) |

| Inner Cord (Core) | W: Cordless, A: Silicone rubber solid, T: Silicone rubber tube, F: Silicone foam |

| O-Ring ID* | R: O-Ring Inner Diameter(mm), * String type unless otherwise indicated |

* O-Ring works: Excellent precise welding and durability by spot welding on connection parts

(Depending on the string OD size and inner cord material, O-Ring’s ID may be limited.)

| P/N | P/N Explanation |

|---|---|

|

Standard force, Sn-plated BeCu + String Ø2.5mm + Silicone tube cord |

|

Low force, Stainless steel + String Ø4.0mm + Silicone solid cord + O-Ring ID 50mm |

No data.